Stage 1 - Modelling

New products traditionally started with the modeller making a model of the product in plaster. This would be around 12% larger than the finished item to take account of shrinkage during the process.

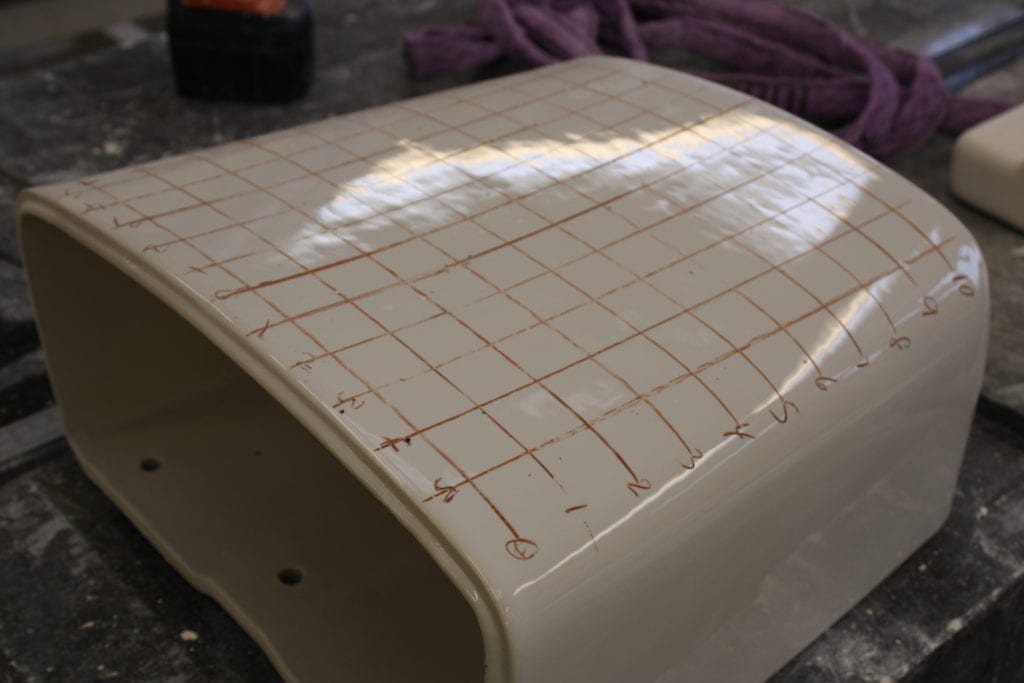

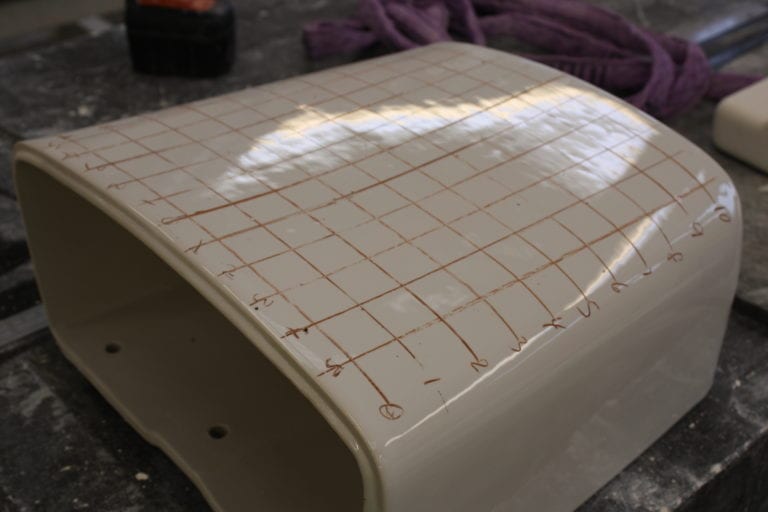

A prototype mould called a block mould would then be made from the model. The block mould would go into trials casting and the pieces made here would be sent through the process. The finished pieces would be checked for dimensions, distortions and manufacturing issues. A grid drawn on the fired piece might be used to identify distortions. Any modifications required would be made to the block mould and the process repeated until the issues were eliminated.

In later years the modeller would use computer-aided design (CAD) to create a virtual model. Combining this with computer-aided manufacturing (CAM) the block mould could be machined directly from a block of plaster. The trials casting process then continued as before.